Technical Information

Technical Information Power And Control Cables

Power And Control Cables Power Appendixes

Power Appendixes CABLING ; Tools , procedure , accessories , laying and handling

CABLING ; Tools , procedure , accessories , laying and handling cable fault finding Guide

cable fault finding Guide صفحه cable fault finding Guide

|

cable fault finding Guide Fault location on communication and power cables is a very specialized area of electrical technology. The performance of effcient fault location is very much dependant on good logistics and knowledge. Fast and reliable fault location is dependent on these factors if prelocation of a fault is to be done with high accuracy. The following pinpointing procedure, for the exact location of the fault location, can be done on a very short segment of the cable. Cable testing, cable diagnosis and partial discharge measurements, will become of higher importance in the future. The condition based preventive maintenance of cable networks, will more and more replace the event oriented maintenance of cable installations. A good detailed knowledge of the construction of cable networks, cable types and their accessories, simplifes the evaluation of the measured results considerably. Many of these are processes are the essential grounds for correct decisions to be made. The types of cable faults and the required steps to do a cable fault location or a diagnosis are one of the most important details that the technician must be aware of. |

|

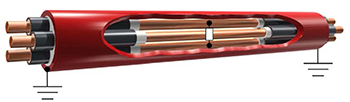

1) Fault Conductor - conductor (parallel Fault) Connection between two or more conductors. The insulation resistance value of the fault can be between zero Ohms (low resistivity) or several M Ohms (high resistivity). |

|

|

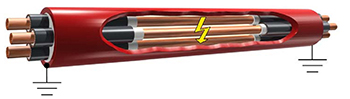

2) Fault Conductor - shield (parallel Fault) Connection between Conductor and shield or Conductor/Conductor and shield. The insulation resistance value of the fault can be between zero Ohms (low resistivity) or several M Ohms (high resistivity). Experience has shown, that most faults are in this category. |

|

|

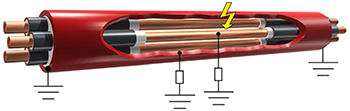

3) Flashing fault (parallel Fault) Very high resistance fault. The cable can be charged. The fashover happens typically at some kV and is very often located in Joints. The cable acts comparable to an arc gap, where the distance between the electrodes determines the voltage. The insulation resistance of this fault is typically infnite up to the breakdown voltage. |

|

|

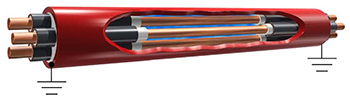

4) Serial fault (Open, Interrupt) Faults of this type can be very high resistive up to infnite (complete cut). Very often these type of faults are a combination of serial and parallel insulation resistances. The reason for this being a complete cut of the cable, or it is pulled out of the joint, which interrupts everything, but also permits fashovers in all possible variations. If the conductor is partially burned off (Aluminium) we speak of longitudinal faults. |

|

|

5) Earth faults, sheath faults Faults between the metallic shield and surrounding soil in case of plastic insulated cables. Faults between the Conductor and surrounding soil on LV and plastic insulated cables. Especially for these type of faults the highest precaution must be taken when using high voltage, this is of utmost importance, since the voltage discharges directly to earth. Resulting an increased potential danger to man and animal. |

|

|

6) Humid / wet faults On multi core cables, often all conductors are affected. The fashover does not always appear at the position where the water entered the cable. The fault resistance is in the range of several k Ohms. At the fault location, impedance changes do occur. Depending on the cable construction (e.g. longitudinal water sealing) these faults can be punctual or widespread throughout the cable. Humidity faults are the most diffcult faults to locate. They have the tendency to change during the fault location procedure, partially in a very drastic manner, which occurs especially in Joints, the fault can become high resistive again after one or two discharges and then cannot be localised anymore. The water gets blown out of the joint and dries up.Other forms of humidity faults are underwater faults. Here the water pressure prevents an effective ignition of the fault during the HV application. The location of these faults can be very diffcult to.pinpoint. |

|